The Lithium-ion value proposition

Simpro estimates that by 2030, all new warehouse equipment with be powered by Lithium-ion battery technology.

Although the warehouse-equipment industry is 3-4 years behind the automotive industry, the same trends towards electrification and Lithium-ion are visible, generally for the same reasons – cost, performance, safety and environmental considerations.

|

|

Lead-acid battery trucks |

Lithium-ion battery trucks |

|

Water refill needed |

Yes |

No |

|

Special charging rooms needed |

Yes |

No |

|

Possibility of damage through operator misuse |

Yes |

No |

|

100% charge time |

10 hours |

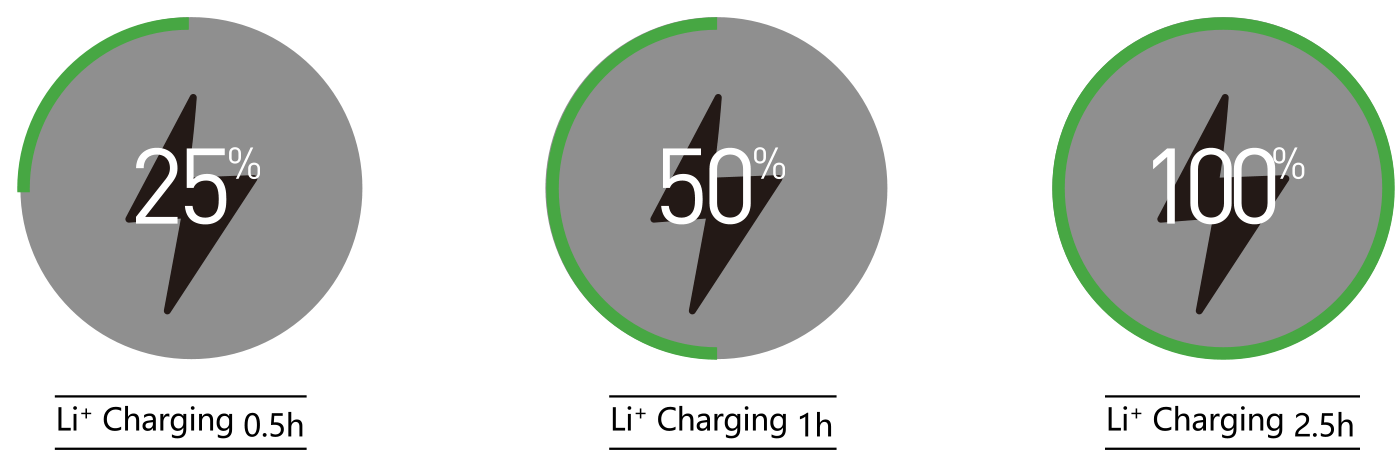

2.5 hours |

|

Battery exchange needed |

Yes |

No |

1.1 Cost

Lithium-ion batteries have an upfront cost about 2x as much as traditional lead-acid batteries. However, in intensive and/or multi-shift operations they typically pay for the cost difference in about 3.5 years, and thereafter have a lower overall cost of ownership. The cost savings are derived from the following areas:

- Approximately ~35% less energy loss to heat than lead-acid batteries

- 8-10 times faster charging, meaning expensive energy-storage assets spend less time connected to the wall and more time in operation

- ~4 times longer service life per battery

- No staff or resources need to be devoted to maintenance, watering and servicing

- No equipment downtime for swapping-out batteries

- Full performance delivered at all times, even in lower charge states

- No space required for charging rooms and battery servicing

- Much reduced H&S hazards with no CO2 or hydrogen emissions, and no heavy battery handling – meaning lower insurance and medical costs

1.2 Performance

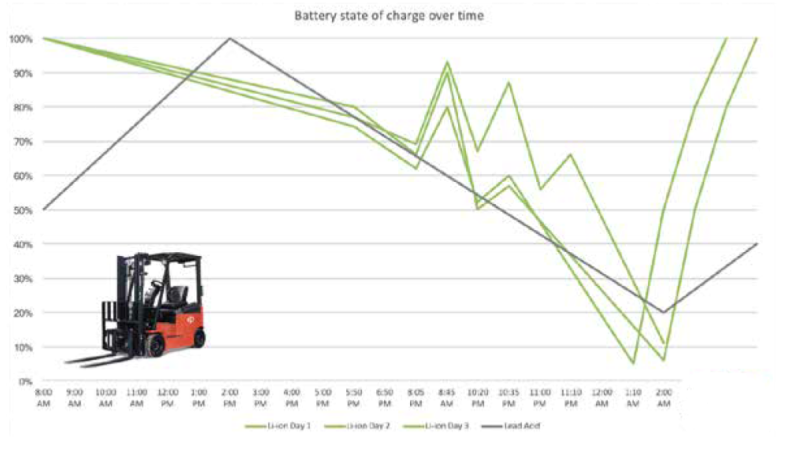

Lithium-ion batteries deliver several performance advantages over traditional batteries, especially for intensive 24/7 operations. The operational mode for Li-ion differs, in that rather than swapping batteries out, Li-ion batteries are ‘opportunity-charged’ during work breaks throughout the day.

- 8-10 times faster charging

- No decline in power output or operational performance as the battery discharges

- Improved stability since the light weight and small size of Li-ion cells allows ballast to be positioned in optimal locations in the frame

- 4000+ cycles per battery

2.3 Safety

Traditional lead-acid batteries have a number of hazardous features which are eliminated with Lithium-ion technology:

- No explosive hydrogen emissions during charging

- No hazardous heavy metals on site

- No manual handling of heavy batteries during swap-outs

2.4 Environment

For equivalent operations, Li-ion batteries have a service life approximately of four times that of a lead-acid battery, dramatically reducing battery disposal needs.

- 75% less battery replacement and disposal than lead-acid

- No emissions of CO2 or hydrogen while charging

- No heavy-metal waste to landfill

3. The Simpro value proposition

Simpro works with large companies who are concerned about the total cost of ownership for their materials handling requirements. The company currently supplies materials-handling solutions to most of New Zealand’s leading manufacturers, including Fonterra, Goodman Fielder, Tegel Foods, George Weston Foods, Heinz Watties and Vitaco.

Simpro has over one thousand units of electro-hydraulic equipment in operation in Auckland alone, supported by a full-time service technician. The company also has five technical staff on call in Auckland, with over 100 years’ combined technical experience.

The cutting-edge lithium-ion technology supplied by Simpro has a proven record of reducing energy bills by over 30%, while eliminating battery maintenance and service costs, the entire battery charging room, and the health and safety hazards present with lead-acid batteries.

- The equipment provided by Simpro enables clients to reduce their total cost of ownership over 10 years by up to 38%, or 20% over 3000 hours on lease.

Simpro is a New Zealand family-owned company in operation since 1986, registered with the New Zealand Companies Office as Simpro Handling Equipment Limited, company no. 1827916.

3.1 Simpro capabilities

- 3-wheel counterbalance forklifts (electric)

- 4-wheel counterbalance forklifts (electric or IC)

- Man-up order pickers

- Pallet trucks (electric and manual)

- Reach trucks up to 11 metres

- Walkie-reach trucks

- Fork attachments and accessories

- Equipment e-monitoring systems

- Training

- Outright purchase or serviced lease terms

- Simpro does not currently have access to stock pickers or turret stock pickers.