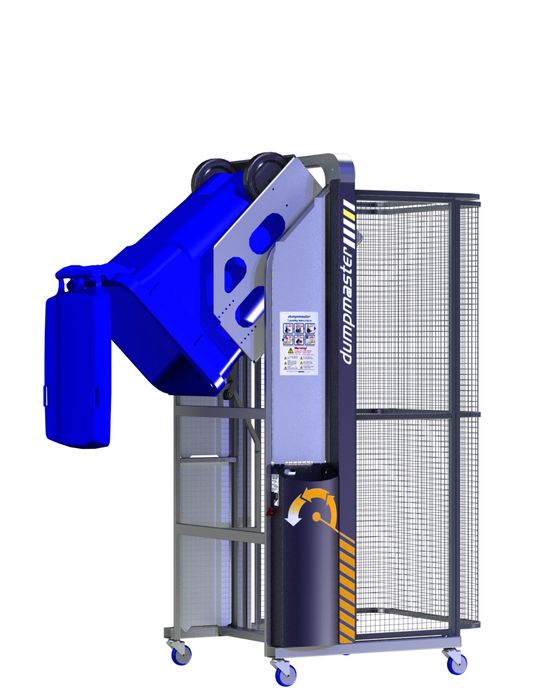

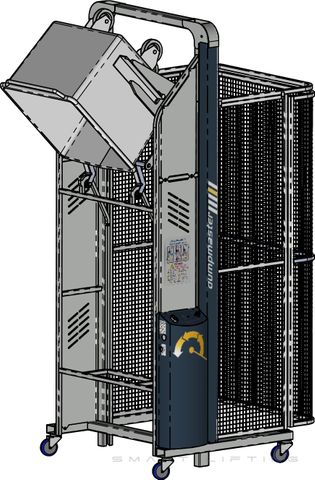

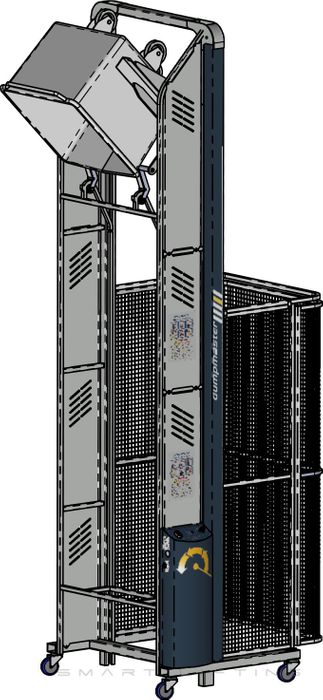

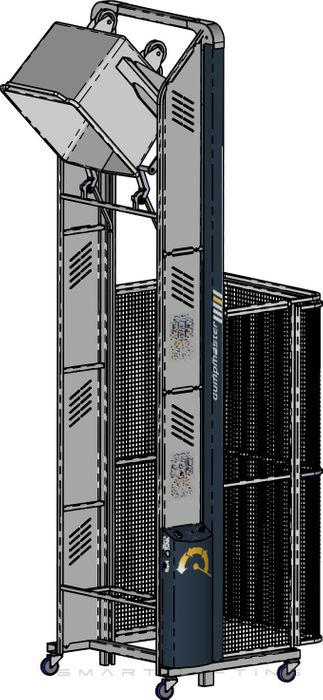

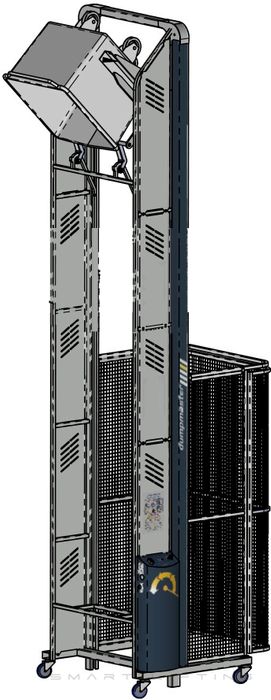

Dumpmaster

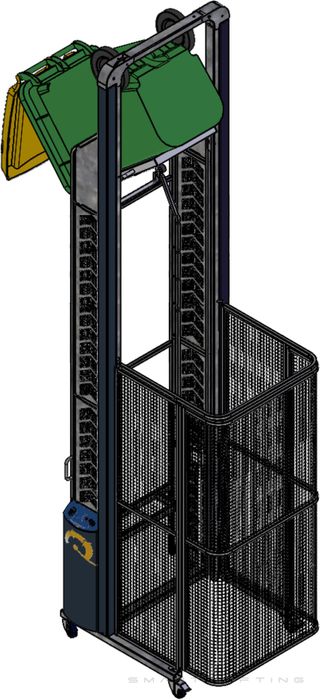

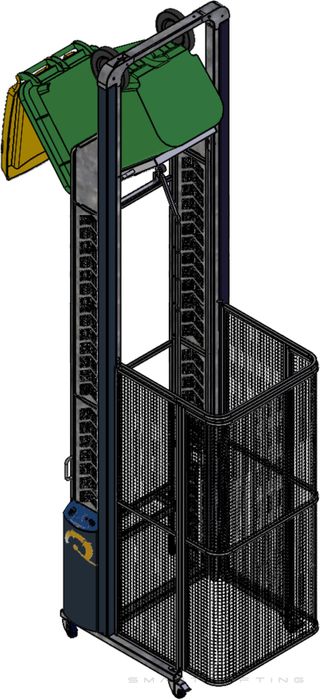

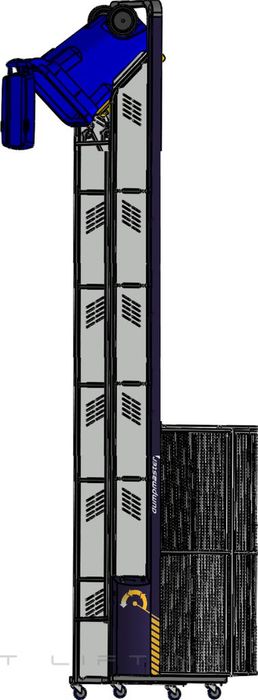

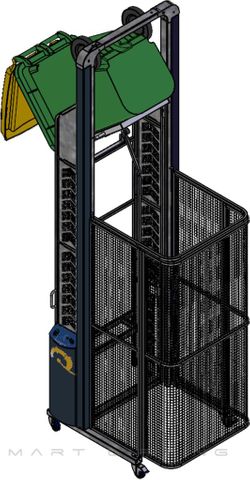

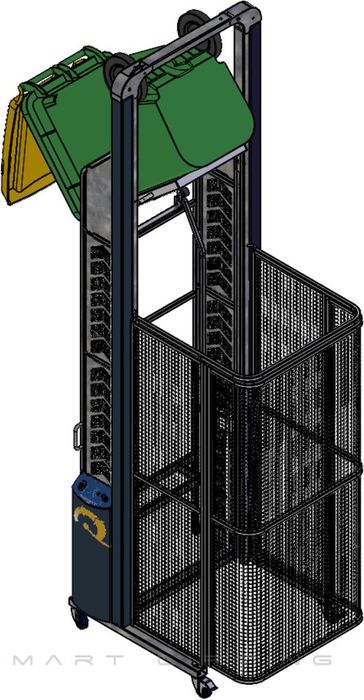

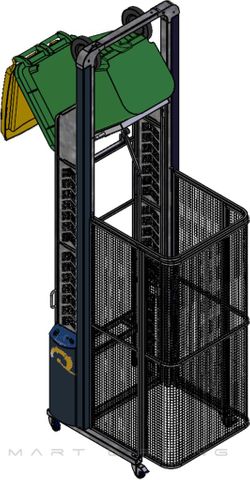

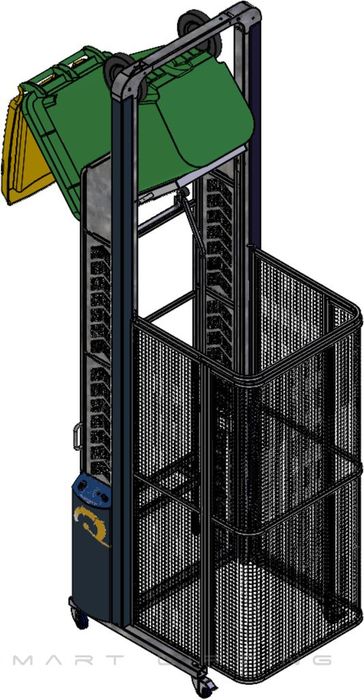

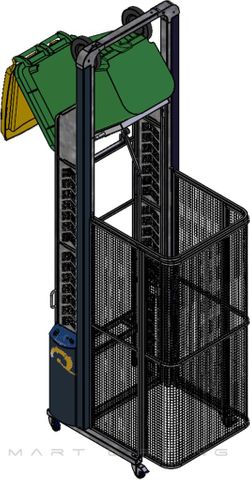

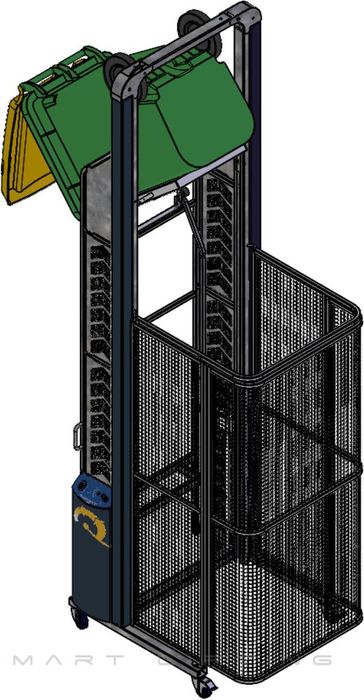

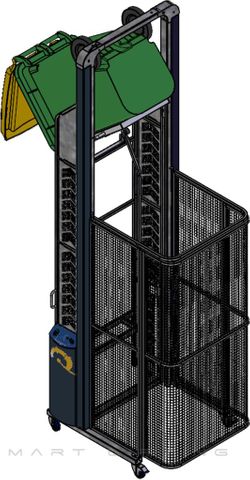

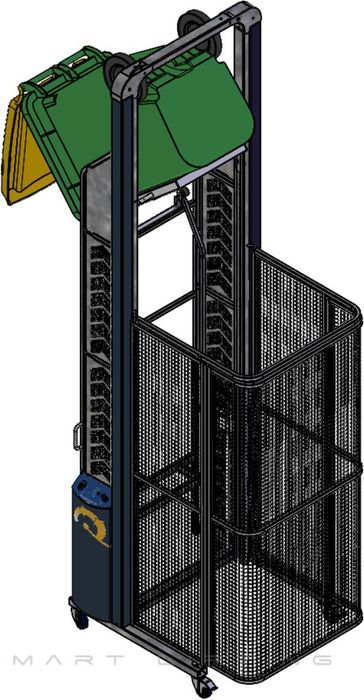

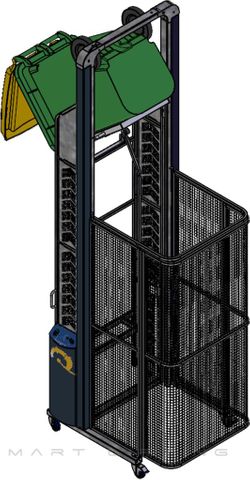

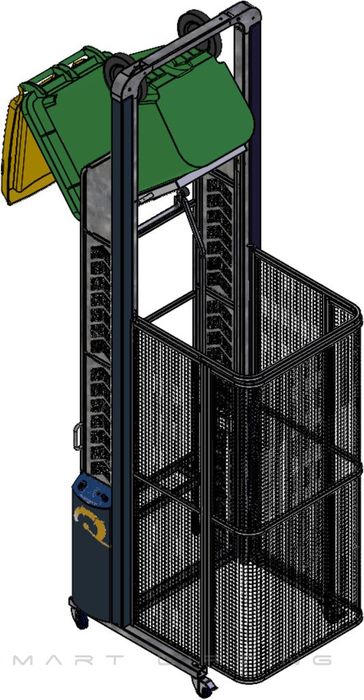

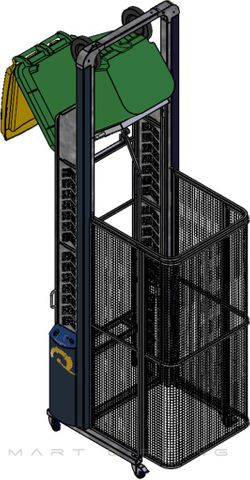

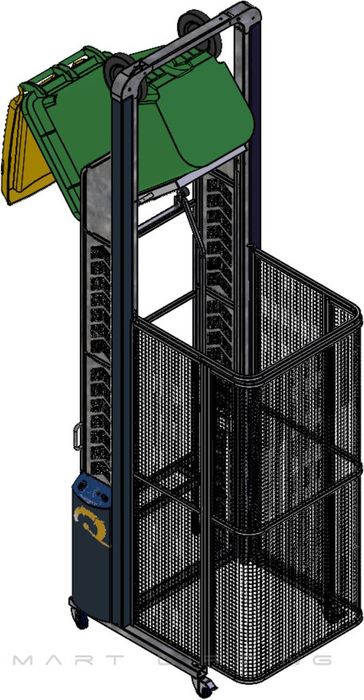

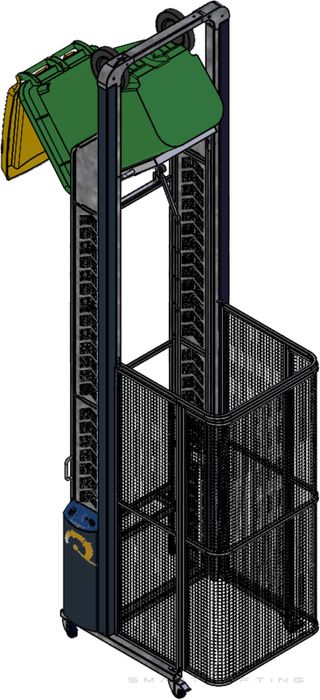

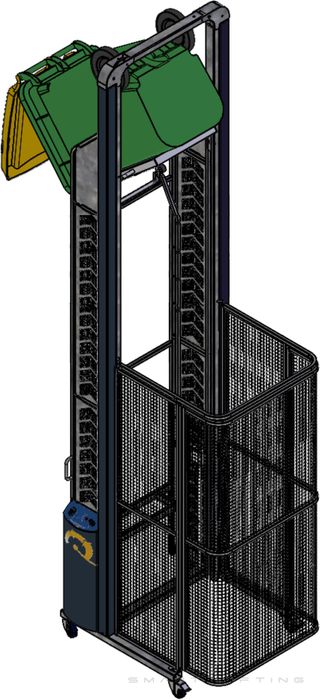

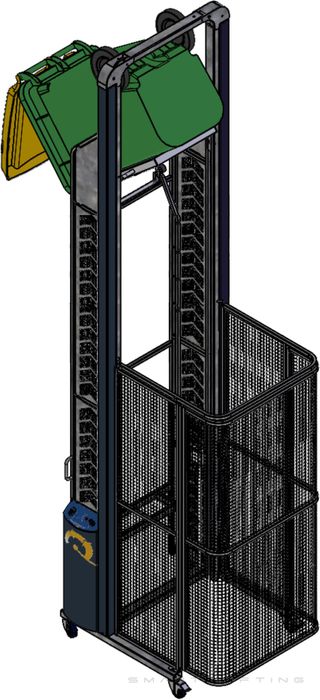

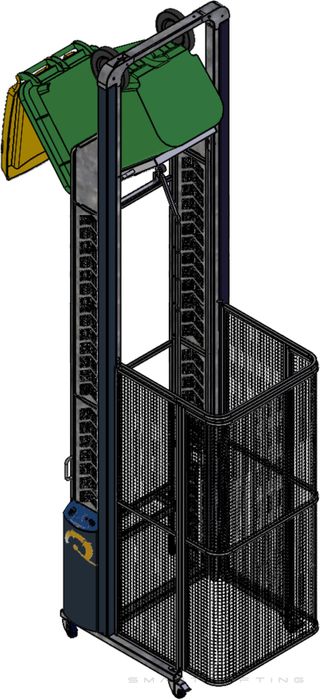

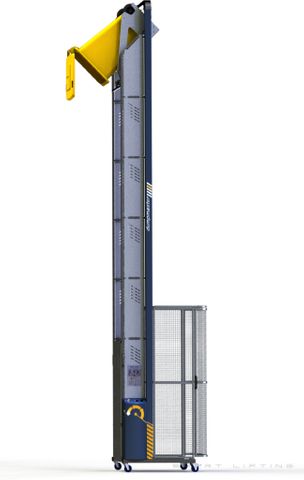

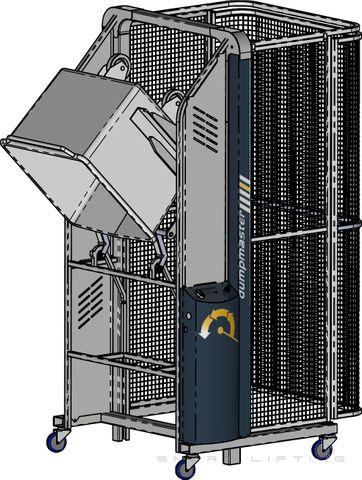

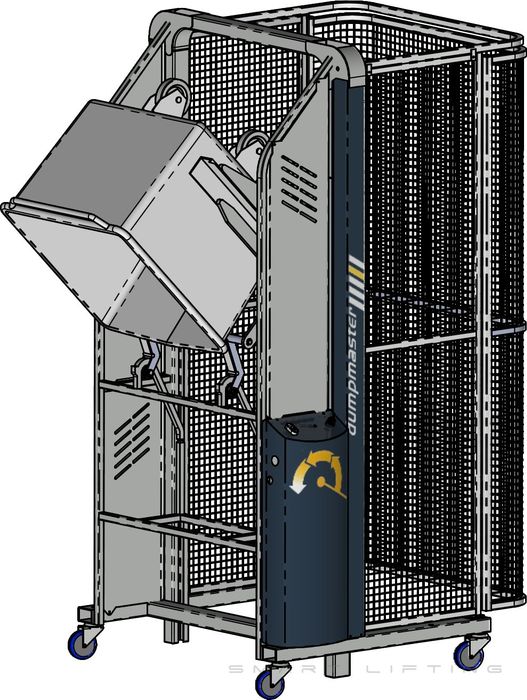

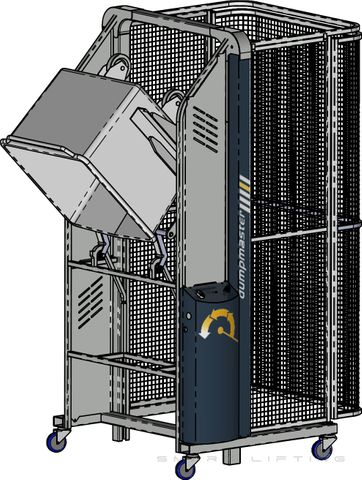

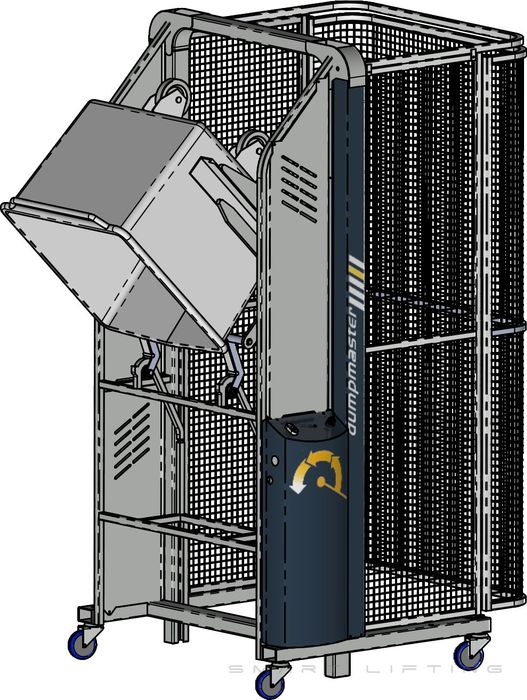

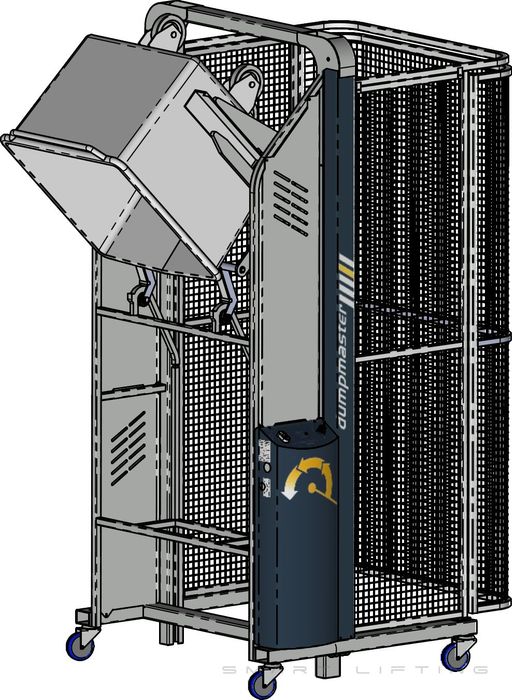

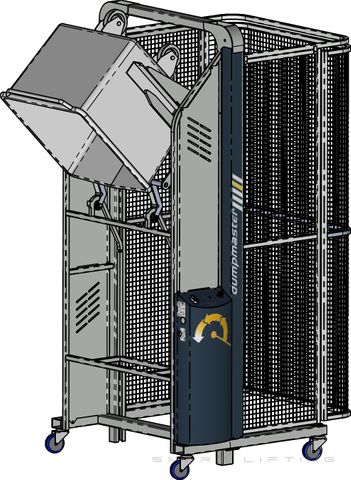

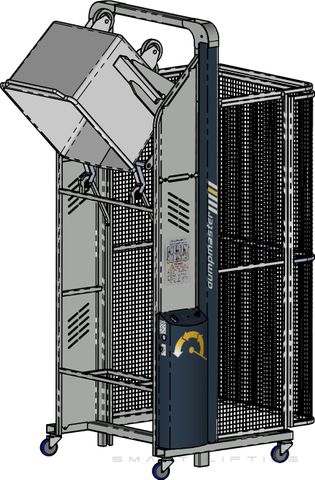

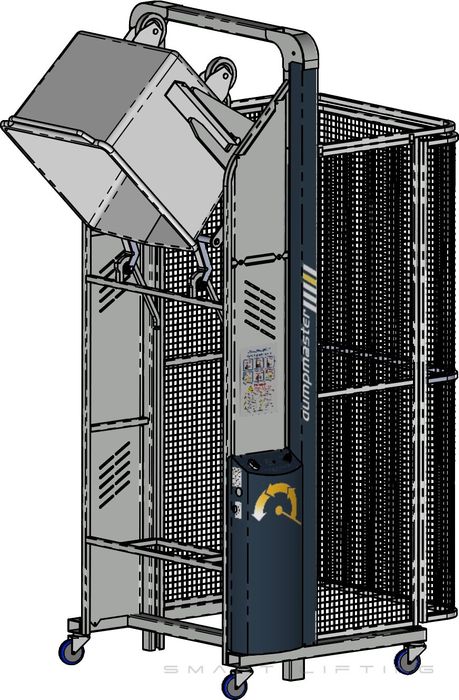

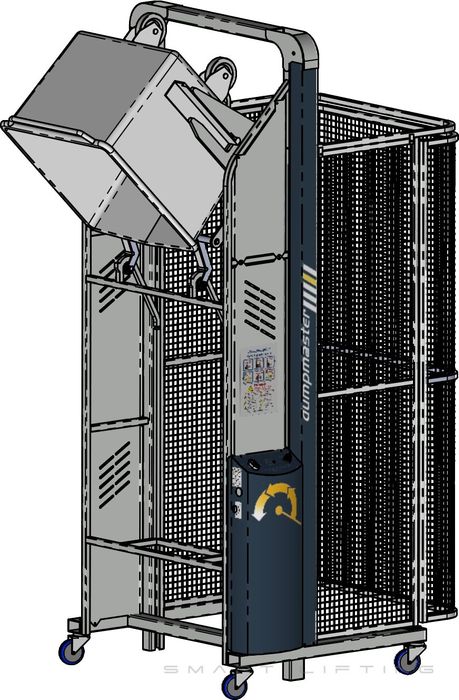

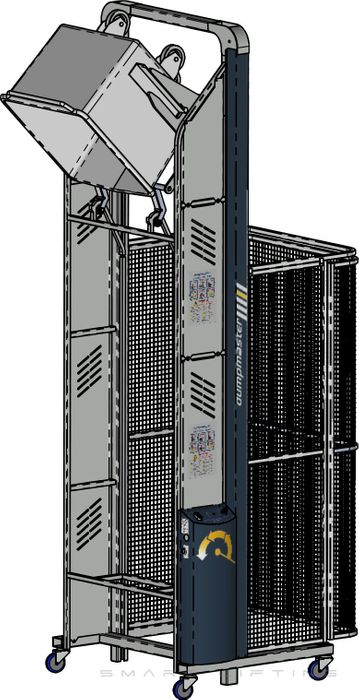

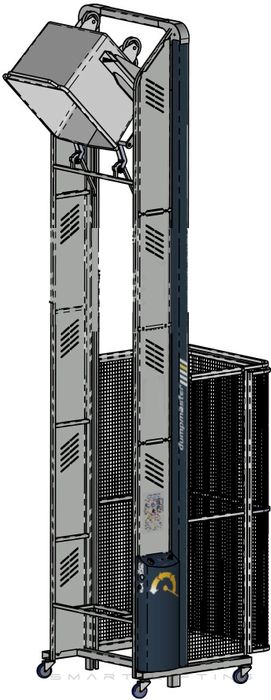

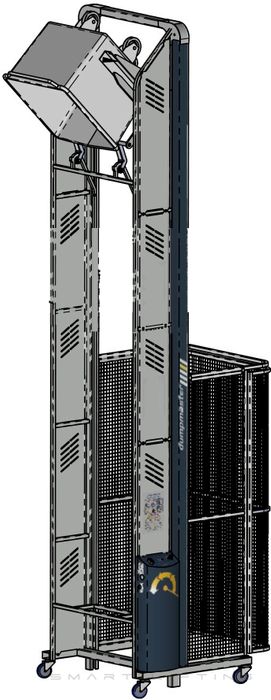

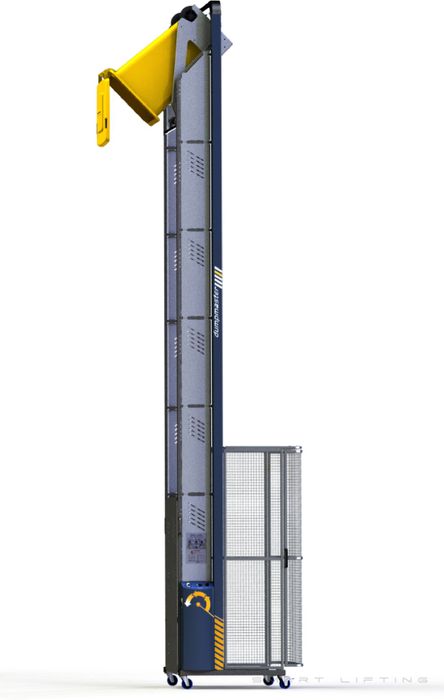

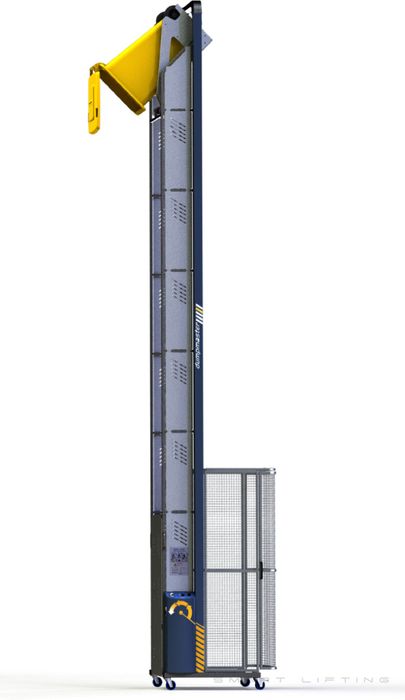

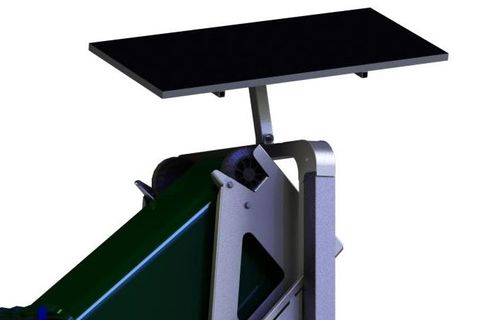

Dumpmaster is a high-speed mobile bin lifter from Simpro, with 250kg capacity and a modular design which can empty almost any bin at any height. The unique hydraulic action lifts bins vertically, then gently inverts them over the destination receptacle, while keeping the centre of gravity safely within the machine's footprint. A complete tipping cycle can take less than 30 seconds.

Standard Dumpmaster models have battery or 3-phase mains powerpacks, but other power options can be specified, including solar panels, 1-phase mains, and even compressed-air. All models are designed for safety, with full-cage guarding, an interlocked door and CAT1 architecture to achieve PLc safety performance; optionally upgraded to CAT3 or CAT4. With a hot-dip galvanised frame and IP55 ingress protection, Dumpmaster needs little maintenance and can be used indoors or out.

In production since 1992, the Simpro Dumpmaster is now relied upon by thousands of companies around the world to save time and prevent injuries. It is made in New Zealand, CE-marked, and backed by a two-year warranty.

- 700-6000mm tipping height

- 250/300kg capacity

- Standard cradles to suit EN840 wheelie bins, DIN9797 Eurobins and ANSI trash carts (custom cradles available)

- Battery, 3-phase, 1-phase, solar and compressed-air powerpacks available

- Duty cycle up to ~4 tonnes per hour

- Tipping cycle 20~60 seconds

- CAT1 safety architecture to achieve PLc safety performance (optionally CAT3/CAT4)

- Service weight 160~570kg

- Castor wheels or bolt-down lugs

- 24 month back-to-base factory warranty (registration required)

| Dumpmaster Specifications | ||||||

|---|---|---|---|---|---|---|

| Model | DM0700* | DM1200 | DM1500 | DM1800 | DM2100 | DMxxxx (custom) |

| Tipping height ("TH") | 700mm | 1200mm | 1500mm | 1800mm | 2100mm | [xxxx]mm |

| Height ("OH") | 1770mm | 2260mm | 2560mm | 2860mm | 3160mm | [xxxx + 1060]mm |

| Width | 964mm | |||||

| Length | 1170mm door closed / 1834mm door open | |||||

| Weight | ~160kg | ~205kg | ~215kg | ~225kg | ~235kg | [xxxx / 30 + 165]kg |

| Capacity (max bin weight) | 250kg | |||||

| Bin compatibility (EN840 cradle) | 60L, 80L, 120L, 140L, 240L EN840 wheelie bins (options: custom cradle) | |||||

| Bin throw ("BT") | ~180mm with 240L wheelie bin / ~105mm with 120L wheelie bin | |||||

| Electrical specifications (battery model) | Onboard digital float charger (input: 85-264VAC 47-63hz, max draw 3 Amps), with 2x 12V 21Ah deep-cycle sealed gel batteries in series configuration, 0.8kW DC electric motor, and 24VDC control circuit (options: solar panel) | |||||

| Electrical specifications (1-phase model) | 1-phase mains supply (120/240VAC 50-60hz, max draw 8 Amps), with Variable Speed Drive (VSD) controller driving 0.75kW AC electric motor, and 24VDC control circuit | |||||

| Electrical specifications (3-phase model) | 3-phase mains supply (380-415VAC 50-60hz, max draw 1.9 Amps), with 0.75kW AC electric motor, and 24VDC control circuit | |||||

| User interface | Raise/Lower buttons, key switch, battery indicator, master lockout switch (options: VSD joystick, autocycle unit with Emergency Stop button) | |||||

| Ingress protection | IP54 (options: IP66, IP69K) | |||||

| Cradle travel speed | 0.4m/s lifting / 0.28m/s lowering | |||||

| Tipping cycle duration | ~20s | ~22s | ~24s | ~26s | ~28s | [xxxx / 155 + 15]s |

| Noise level at operator’s ear | ⪅ 60dB(A) | |||||

| Materials | Hot-dip galvanised mild steel frame, galvanised mild steel cradle, 25x25x2.5mm zinc-plated wire mesh guarding (options: sheet metal guarding, polycarbonate guarding, full or partial 304 or 316 stainless steel) | |||||

| Door | Left-hinged door with solenoid-operated electrical safety interlock (options: right-hinged door, swing-up door, roller door) | |||||

| Mounting | ⌀100mm Blue Resilex castors (options: ⌀200mm castors, bolt-down lugs) | |||||

| Applicable Standards and Certifications | AS/NZS4024, ISO 13849-1, IEC 62061, Conformité Européene (CE), EN 349 1993, EN 574 1996+A1:200, EN 953 1997, EN ISO 4413 2010, EN ISO 12100 2010, EN ISO13849-1 2006, EN ISO 13857 2008, EN 60204 2006+A1 2009, EN61000-6-2 2005, EN61000-6-4 2007, Machinery Directive 2006/42/EC, Electromagnetic Compatibility Directive 2004/108/EC | |||||

*The DM0700 model is normally specified as the Dockmaster variant, optimised for emptying bins from elevated loading docks and platforms.

A well-made, well-engineered solution to a potential significant manual handling issue on any building site. With the incorporation of the Dumpmaster within our waste management plan we have seen a definite improvement in site cleanliness with the benefit of not having to replace broken bins and double handling waste.

Matthew Bidewell - Project Manager - Morgan Sindall UK

24-Month Back-to-Base Factory Warranty. Registration is required